Design & Development of the Victory Vegas: Part 1

By Michael Dapper

In this original blogpost, Victory Motorcycles 1998–2017 author Michael Dapper dives into the conception of brand’s most beloved bike, the Vegas, with insight from Victory Product Manager Gary Laskin.

Banner image: Per Gary Laskin (who is seen in the blue shirt near the front wheel): “This was taken on Valentine’s Day, 2002. I believe this was when the first ‘PV’ (Production Verification) bike was built. Notice the side covers and tank badges are still missing.” The Victory Vegas was introduced to Victory dealers in July 2002 as a 2003 model, and it went into production late that year. Gary Laskin

Turn the clock back to January 1998. The Victory V92C had been introduced, but production of that original Victory model wouldn’t begin for another six months. On Jan. 19, 1998, Gary Laskin joined Victory as its original Product Manager. His career background was in retail marketing for department stores and apparel brands, “but I’ve always been a major gearhead, spending a lot of time in the garage with my dad” as a youth, and he landed the Victory job.

That fall, Laskin attended a rally in Loudon, N.H., “and it was just frickin’ miserable,” he recalled. “It was raining and it was cold. We had this little booth outside in the mud, and I was just trying not to get sick. I was looking at all these bikes with 21-inch front wheels. I’m watching all these bikes ride by us and thought, damn, there’s really a lot of bikes with 21-inch front wheels.”

Models like the Harley-Davidson Wide Glide had the 21-inch front wheel, and Laskin learned the Milwaukee-based company sold a lot of them.

“I went through the industry data, researched Harley-Davidson sales of 21-inch bikes, and at the time, 45% of [the bikes HD sold] had 21-inch front wheels. I had never looked at the market like that before, but it turned out it was a big, big thing.”

A tall front wheel and fresh, smooth styling were integral to a new Victory project that carried the code name “CC,” or “Custom Cruiser.” That model, eventually known as the “Vegas,” reflected the Victory staff’s collective desire to offer cruisers with fresh, new, and modern style.

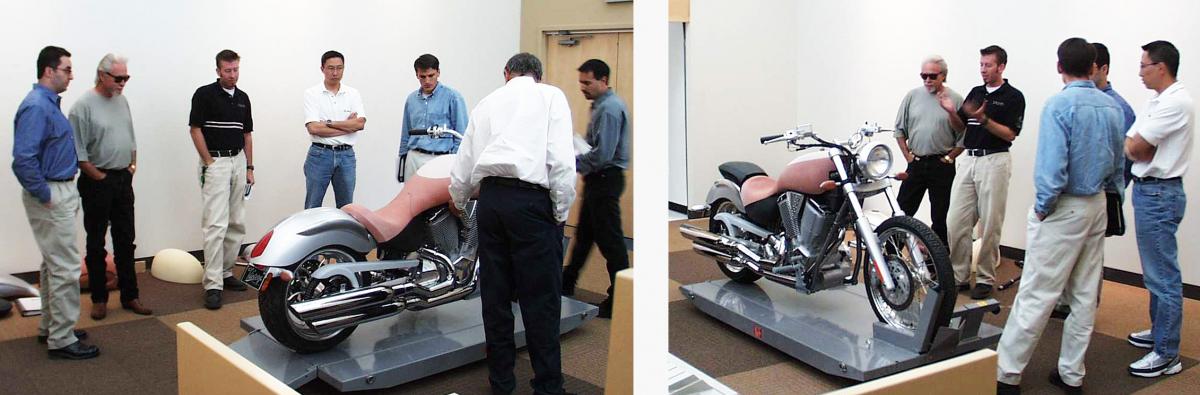

These photos were taken during development of the Custom Cruiser (it was not yet named the Vegas). Victory styling consultant—and Victory dealer—Arlen Ness (in sunglasses) is shown with members of the Victory team reviewing an in-process model of the bike. This was shot in the Industrial Design area of Polaris corporate headquarters in Medina, Minnesota. Gary Laskin

These photos were taken during development of the Custom Cruiser (it was not yet named the Vegas). Victory styling consultant—and Victory dealer—Arlen Ness (in sunglasses) is shown with members of the Victory team reviewing an in-process model of the bike. This was shot in the Industrial Design area of Polaris corporate headquarters in Medina, Minnesota. Gary LaskinLaskin recalled: “Todd Dannenberg was ID [Industrial Design] manager, and [Industrial Designer] Mike Song did the basic design. We had done a bunch of sketches and took them to focus groups. The customers kept repeating back to us, ‘smooth flowing lines’—that was what people wanted. That was the whole direction behind the bike.

“The raised spine [on the fenders and fuel tank] was a feature that was inspired by the ‘60s muscle cars, and it ties the flow of the design together. The tank flows into the seat, it’s all integrated. It was very different from what Harley was doing where every component was separate. We wanted it smooth and flowing, as the customers had defined it.”

As noted in the Victory history book, Mike Song designed the Vegas, contrary to the urban legend that it’s a Ness design. Some consumers were convinced the Vegas taillight design was the Arlen Ness logo, but it was actually a Song design—one for which he has a U.S. patent.

“Mike Song designed the bike,” Laskin said. “Arlen and Cory [Ness] were brought in as consultants and they offered us direction. They were reacting to sketches that our guys in ID [Industrial Design] did. We brought the Nesses in and we had 16 sketches, and they offered their input. They helped us narrow it down. I would say they had influence on the design, but it’s Mike Song’s design.”

At a time when the Victory model lineup consisted of only the V92C and V92SC SportCruiser, the Custom Cruiser was developing nicely.

“We had the original [CC] concept done in the fall of 1999,” Laskin remembered. “At that time, it used the same frame and swing arm as the V92C, and had the SC taillight because we were very limited in our budget.

“[Original Victory General Manager] Matt Parks had left, [then-Polaris President Tom] Tiller was our temporary GM, and he wouldn’t approve it until we got a new business leader. [New General Manager] Mark Blackwell and [Head of Engineering] Allan Hurd, joined Victory in 2000, and Allan thought we should take [the CC] further, so we stretched the swing arm, made it an aluminum swing arm, created the flush taillight, and that really completed the look of the bike.”

Tooling for the distinctive Vegas fuel tank was so expensive, it burned through most of the project’s development budget.

“We ran out of tooling [funds] by the time we got to the headlight,” Laskin recalled. “We needed a 7-inch headlight. Allan came from Excelsior-Henderson [EH], and they had a round headlight that they weren’t using anymore, so we used the Excelsior-Henderson headlight bucket, but with a different bezel and interior light.

“And because we ran out of tooling money, the guts of the speedo were off the shelf. It was a speedo made for Buell, and we changed the face and needle and bucket, but the guts were originally made for Buell. That wasn’t uncommon. That’s something that a lot of suppliers will do.”

Gary Laskin said this is a photo “of the final hard model of the Vegas. It is not a real bike. You can see some parts changed slightly between this model and the production bike. The headlight is an off-the-shelf aftermarket unit, the speedometer gauge bucket is not real and not really chromed. The reflectors are just tape and do not reflect the final design.” On hard model bikes, he said, details “were constantly changing, [and this one] changed a lot, but I believe we would have taken it to focus groups looking like this. The overall, basic style and shape didn’t change much from this hard model to production. Just small details.” Other details Gary noted: the turn signals were changed prior to production; the rear turn signal location is different from production; “the side covers are a different shape, [there was] no room for swingarm movement!; no oil cooler; and “the foot controls, they are aftermarket, or possibly factory H-D parts. Rich Christophe actually designed the production, aluminum foot controls when he was an intern at Polaris back in the day.” Gary Laskin

Gary Laskin said this is a photo “of the final hard model of the Vegas. It is not a real bike. You can see some parts changed slightly between this model and the production bike. The headlight is an off-the-shelf aftermarket unit, the speedometer gauge bucket is not real and not really chromed. The reflectors are just tape and do not reflect the final design.” On hard model bikes, he said, details “were constantly changing, [and this one] changed a lot, but I believe we would have taken it to focus groups looking like this. The overall, basic style and shape didn’t change much from this hard model to production. Just small details.” Other details Gary noted: the turn signals were changed prior to production; the rear turn signal location is different from production; “the side covers are a different shape, [there was] no room for swingarm movement!; no oil cooler; and “the foot controls, they are aftermarket, or possibly factory H-D parts. Rich Christophe actually designed the production, aluminum foot controls when he was an intern at Polaris back in the day.” Gary LaskinWatch the Octane Press FUEL Blog for “Design & Development of the Victory Vegas, Part 2,” which will cover the fuel tank design, the iconic original Vegas publicity photo, and more.