Clessie Cummins Biography: A Childhood Survived

The following is an excerpt from The Diesel Odyssey of Clessie Cummins by C. Lyle Cummins, Jr: a lively historical account of an American entrepreneur and inventor best-known as the father of the American diesel truck. This Clessie Cummins biography ranges from his early exploits as a boy genius through the founding and success of his global brand and company. In this excerpt, read about how diesel inventor Clessie Cummins's inventive streak manifested itself through a series of boyhood mishaps and adventures.

Clessie’s inventive talents surfaced while living in two Ohio towns between the ages of eleven and fifteen. “I was born with a terrific yen for mechanical things and can’t remember when I wasn’t trying to build something. If I wanted a wagon, I had to make one. All were exact imitations of the hoop mill’s log wagons with bolsters to fit any kind of body that was required. Every move we made found me making an immediate acquaintance with the local blacksmith.” Forbearing and forgiving parents often feared what he might do next, but they perceived his intense desire to explore and experiment and adopted a prideful acceptance to give him a long rein. His youthful escapades were often disastrous but never malicious or revengeful.

Clarksville, a village in the hilly part of southwestern Ohio, formed a backdrop for opening scenes of Clessie’s boyhood antics and activities.

I had a tremendous amount of fun there and can vividly recall many of the faces and places I encountered. The bottom land along the several streams was heavily wooded. The area was quite interesting to paleontologists because fine specimens of prehistoric sea life could be found in the banks along the streams. Each summer the scientists would arrive to dig for specimens, and they would also buy from us what we had found for about five cents each. This seemed like a pretty fair profit for something that was fun finding anyway.

Old forts and landmarks left from Indian times were still quite numerous, and the history of the countryside made a great impression on me. In fact, an Indian family lived very near us. There were four boys, and the father was a hunter and fisherman with whom I spent many hours.

The little town also had a blacksmith named Gus Miller who was a most likeable fellow. He took great interest in the youngsters. I was wild about the opportunity to pump his forge while he repaired wagons, and eventually became able to do some forging myself while he made the repairs. I made two or three little wagons plus a sled.

The town owned a large bobsled which held nearly fifty people. Miller was the steersman for the sled. When the snow conditions were right we had some exciting times. A horse was used to pull the sled up the hill. Near tragedy resulted on one ride when the local school teacher, a man half the size of the blacksmith, lost control after the sled hit a bare spot and crashed into a log house. Its sole occupant was an elderly woman who traditionally gave us a bad time. The sled broke through the front door, and some of kids piled into the living room where she was seated in front of her stove. We all left in a hurry while she went into the kitchen to grab a broom to shoo us off. No one was seriously hurt, but the teacher was on the hotseat for a while for having taken such a chance. What saved us was that he had started from only halfway up the hill. Otherwise he might have killed some of us.

I saw my first automobile in Clarksville when it was passing through and had difficulty ascending this same hill. A bunch of us boys helped the driver by giving it a push to the top. What an impression it made on me.

Gus Miller also figured in a rescue mission for Clessie. He and some boys were swinging from a long rope tied to a tree limb which let them arc out and drop off into a stream. The game was to see how far out one could land in the water. Once, when Clessie was making a maximum effort, either the rope or the limb broke and he landed on the bank on his arm. The sight of an immediately formed second arm joint, with one of the bone’s ends sticking through the skin, ended the contest. A messenger dispatched to fetch someone to carry Clessie back had difficulty arousing interest because he reported that Clessie had “sprained” his arm. Not until describing the degree of sprain was help forthcoming. The husky blacksmith carried Clessie back slung over his shoulder with the broken arm painfully dangling free. Setting the arm consisted of Gus pulling on one end and another man on the other, with the local doctor making final adjustments. The job was done so well that an x-ray years later showed little evidence of the break. The unknown treatment at the time to avoid infection was undoubtedly something which provided a burning sensation.

That same doctor also treated Clessie after one of his pyrotechnic exploits. A local Fourth of July custom was for Gus to place a sizeable charge of black powder under one of his anvils to see how high it could be blasted into the air. A less publicly-approved event, was to demonstrate the town’s largest firecracker. Clessie’s unilateral entry was a homemade cannon to be discharged at sunrise from the front porch of his school. The powder quantity is not known, but when ignited it was sufficient for the too-fragile cannon to rupture and damage the schoolhouse door, and in the process inflict powder burns on a lucky but frightened amateur artilleryman. Clessie beat a hasty, unseen retreat to the doctor’s home and awakened him. Part of the treatment included a stern admonishment. True to his oath of confidentiality, the doctor kept silent as to who had been the culprit in the explosion, but the patient would carry a few imbedded powder flakes to his grave.

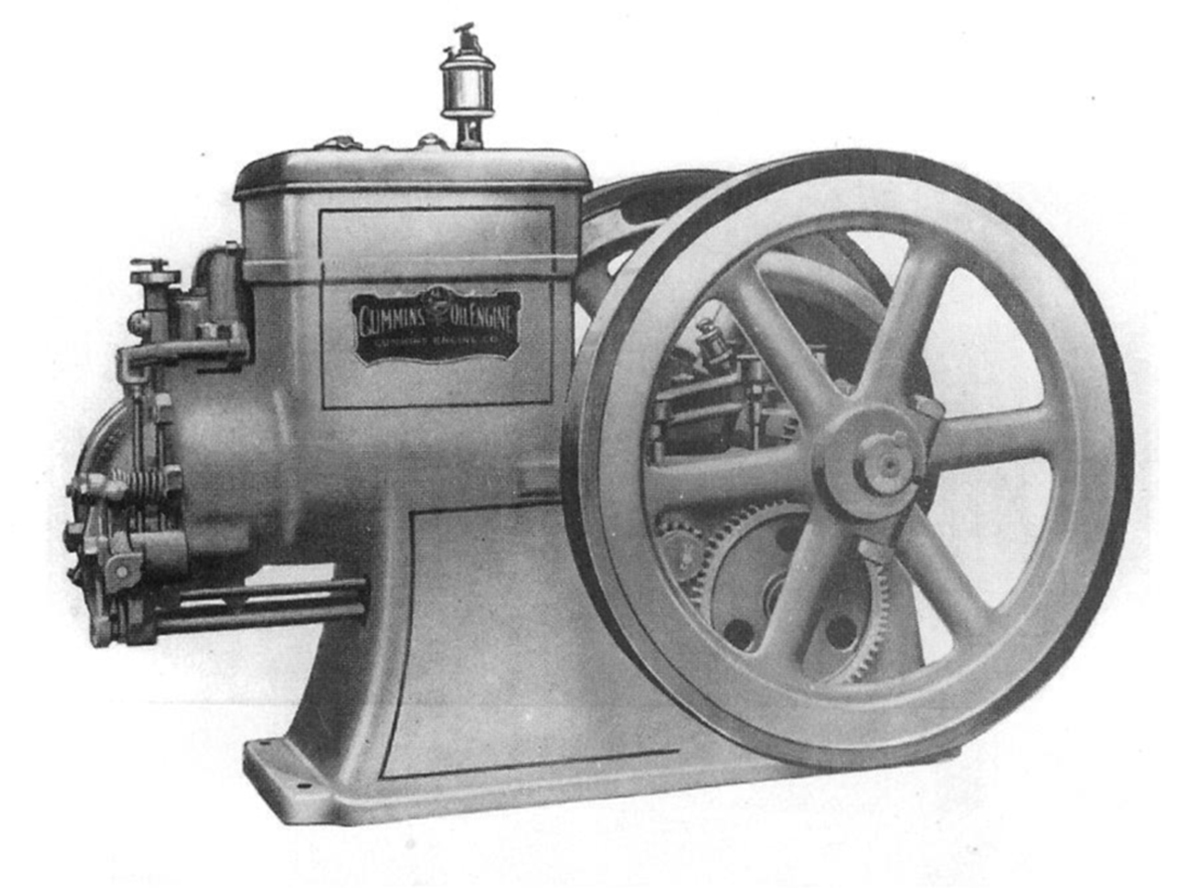

After brother Don was born, Clessie enjoyed for the first time a period of decreased supervision because his mother was in poor health for some months after the delivery. This may help to explain numerous happenings. It was in Clarksville where Clessie, about age eleven, first went into the engine business and made other assorted machinery.

An old clockmaker showed me how to build a tiny steam engine using 8 or 10 gauge brass shotgun shells. Slightly altered pennies formed the pistons. It was an oscillating cylinder type engine, soldered onto a tube which was in turn soldered to a one gallon kerosene can. The latter became the boiler which frequently blew up. Fortunately, no one was ever injured but a couple of mothers were singed while their sons’ engines were running on the cook stove and the boiler ruptured. Although sales flourished for a time, it was the mothers who raised a protest which closed down my business.

I once gave my own mother a scare, and gave myself another lesson in metal working. I was doing some lead molding on the kitchen stove while she had a fruit canning project underway. My wooden mold had been left outside in the weather and was quite damp. When I poured in the molten lead, the moisture in the mold instantly turned into steam which split the mold. Some of the sprayed molten metal landed on Mother. The only real pain either of us received in the potentially serious mishap was my posterior from a spanking.

Dried beans were the main winter staple food for many of us in Clarksville, and shelling them was a major chore for children. After one bean harvest I offered my shelling services to a couple of ladies who sold them in their store. When I saw the mountain of pods, I decided there had to be a less labor intensive way to do the job. With the aid of the man who ran a carpenter shop, I managed to lathe turn a round cylinder into which I drove a row of nails along it. I left the nails sticking out about an inch, but cut off the heads. A frame whose ends supported the cylinder also contained a row of nails such that when a hand crank was turned the nails on the cylinder passed between the nails on the stationary frame. As the horizontal cylinder turned, the dried pods were fed from a hopper into the intermeshing nails and onto a shaker. Separated from the chaff, the shelled beans fell into a sack underneath. At least this was the plan.

With all in readiness, I fed beans into the hopper while two friends took turns cranking the huller. One important factor overlooked was quality control. Distracted by pouring beans and the furious turning of the crank, I failed to inspect the final product until too late. The pins had been set too close together and more than a third of the shelled beans were badly cracked or broken into small pieces.

According to Clessie’s mother, the understanding women forgave him, but there was more split bean soup than usual eaten the next winter.

For more stories like this one check out the related books linked below! For more excerpts of The Diesel Odyssey of Clessie Cummins—the most authoritative Clessie Cummins biography in print and the greatest insight into the life of the diesel inventor—check out the related content linked below.