International Harvester's Fast-Hitch

The 100th Anniversary of the revolutionary Farmall tractor is celebrated in Farmall Century: 1923–2023, the authoritative model-by-model history that traces the evolution and design of the most significant farm tractors of the 20th century. Award-winning author Lee Klancher chronicles how and why the Farmall tractor came to exist and how it evolved with his signature blend of compelling stories, engaging text, and spectacular images. In this excerpt, read about the development of Fast-Hitch.

International’s proprietary hitch system, dubbed Fast-Hitch, was its answer to the Ford-Ferguson three-point hitch. The development most likely began on the “Frameall” tractors, an effort by IH to counter Ford’s new hitch. Ferguson’s system was effective and popular. After Ford and Ferguson split up, the three-point became available to any manufacturer, but it wasn’t available for free. The long tradition of IH using in-house equipment—carburetors, magnetos, and so on—was not about to be dropped to use a feature that was developed on the Ford.

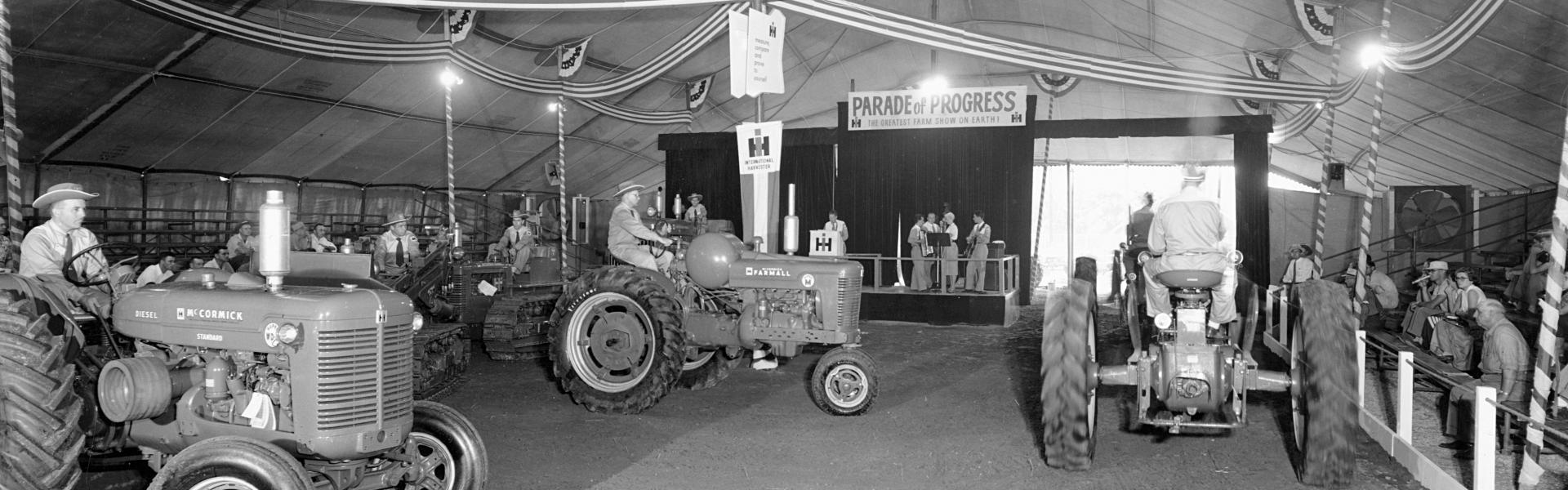

Fast-Hitch was introduced in the first half of 1953 at a show held under a big circus tent at the experimental IH farm in Hinsdale, Illinois, as part of a rollout of seventy-seven new (or improved) pieces of IH equipment. The star of the show was the new hitch demonstrated on Farmall Super C tractors as part of the “Parade of Progress” promotion in 1953.57 The tractors put on a square dance display, showcasing how quickly and easily users could connect their machines to implements using Fast-Hitch. These square dances were repeated at state fairs around the country, including in Minnesota and North Dakota.

The display was clever and effective, as Fast-Hitch’s advantage over the Ferguson system was its ease of mounting. The operator could simply back the tractor into the implement and go, rather than compete in the wrestling match involved in attaching an implement to Ferguson’s three-point system. The drawbacks (for the end user) were that Fast-Hitch implements had to be purchased to take advantage of the new system, and the implements could not be used on other brands of tractors.

IH engineers also developed Fast-Hitch to solve the Ferguson system’s problem of erratic draft. The plow wouldn’t come right out of the ground, but it would vary in depth as soil conditions changed.

In 1945, Gordon L. Hershman came to IH from the military, where he had worked on hydraulics for firing rockets from ships in World War II. He ended up working on Touch Control hydraulics and then developed a hitch to compete with the Ferguson system. He explained that the engineering group felt that the Ford-Ferguson hitch provided erratic draft control, which meant that fields were worked unevenly and inefficiently. “If you were plowing a field and got into heavy going, it came out of the ground. If you were trying to plow 8 inches deep, and you were in different soils in a field, the damn thing would be 8 inches sometimes, and other times it’d be 4 inches. We didn’t think that was much good. That’s why we came up with the Fast-Hitch.”

Besides the advantages of improved draft control, Fast-Hitch was also much easier to hook up. Engineer Robert Oliver also worked on developing hitches, and he recalls that Fast-Hitch was well received because of easy access. “The tools were getting bigger and bigger, and it was much easier to hitch up than to pound those links on with your heel, or [muscle] those tools around to get ’em lined up. With Fast-Hitch, you could just back in, pick up, and go. It was very popular."

Despite the advantages of Fast-Hitch, the buyer still preferred the three-point hitch, so IH looked to develop one. The company looked closely at existing three-point hitch designs and built its own system with an eye toward avoiding the weaknesses of the Ferguson hitch.

The improved hitch featured Traction Control, which allowed the operator to vary the amount of ground pressure on the rear tires with four different settings. The system was mechanical and automatically matched ground pressure to load in any of the four settings. The problem of erratic draft control was solved. “It could go over the terrace and the tool never left the ground. It had the best regulation curve in the industry,” Oliver said. Fast-Hitch was slowly phased out as the three-point hitch became an industry standard.

For more stories like this one, check out the Related Books linked below!